MANUFACTURING

CAPABILITIES

MANUFACTURING CAPABILITIES

Diverse production processes for optimal vessel manufacturing

Binder presents an extensive range of products, ranging from pressure vessels to process vessels, agitator vessels, fermenters, and WHG vessels. Additionally, we offer customized plant and machinery construction tailored to the requirements of the pharmaceutical industry. Our versatile manufacturing capabilities cover a wide spectrum, including welding/cutting technologies, orbital welding, pipe bending, grinding techniques, and pickling processes.

In the welding field, we specialize in plasma keyhole technology, which we employ in both longitudinal and circumferential welds on our semi-automated systems. We perform TIG, MAG, and Plasma Orbital welding. With plasma keyhole, we can weld 8 mm single-layer and 12 mm double-layer plates.

For cutting, we use waterjet cutting technology at 3600 bar. Thicknesses of up to 150 mm can be cut using this method.

Grinding technology holds a prominent position in our company as we utilize state-of-the-art technologies, including vessel cylindrical grinding systems with an impressive diameter of up to 3500 mm and surface grinding systems for extremely precise surface finishing.

The piping section additionally encompasses orbital welding, pipe bending, and endoscopy technologies.

After the welding process, we can further process our components on our machining centers and lathes, allowing us to achieve very tight tolerances that cannot be achieved through welding alone.

In the pickling area, we prioritize the highest quality and use both immersion and spraying methods. This ensures that the surface treatment is uniform and of premier quality.

Our manufacturing capabilities span a broad spectrum, ranging from shearing to highly precise drilling, milling, and turning operations. This diversity enables us to meet the varied and individual requirements of our customers.

MANUFACTURING AND TECHNOLOGY

Welding Technology

- Plasma keyhole up to 8 mm single-layer, 12 mm double-layer

- TIG

- MAG

- Orbital welding

Cutting Technology

- Waterjet cutting up to 150 mm

- Hand Plasma

Grinding Technology

- Vessel cylindrical grinding system up to ø 3500 mm

- Flat surface grinding system

- Sheet deburring machine with vacuum table

Pickling

- Immersion in various-sized tanks

- Spraying

Manufacturing Capabilities

- Shearing up to 4000 x 12 mm

- Bending up to 4000 x 4 mm or 3000 x 6 mm

- Rolling up to 3000 x 12 mm

- Pipe bending Ø10 – 60.3 mm with or without mandrel

- Boring mill

- 3-axis milling

- 5-axis milling

- CNC lathes up to Ø450 mm

- Cycle-controlled lathe up to ø 1300 mm

Part Marking

- Etching

- Laser marking

- Engraving

Inspection Procedures

- Dye penetrant inspections

- X-ray inspections

- Surface roughness measurements

- X-ray fluorescence analysis (RFA) (material analysis)

- Ferrite content measurements

- Visual inspection of weld seams

- Endoscopy

Approvals

- AD2000, HP0

- EN 13445-4

- EN 13480-4

- Pressure Equipment Directive Module A2

- Water Management Act § 19 (WHG)

- EN ISO 3834-3

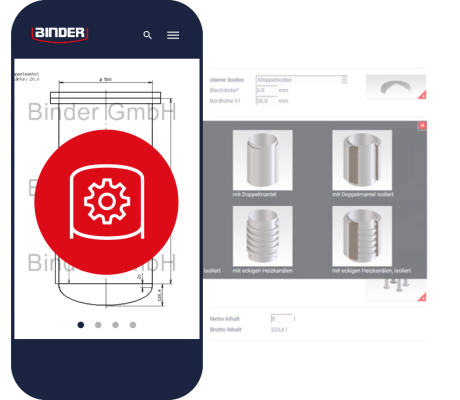

CONFIGURE IT YOUR WAY!

Binder vessel configurator

The BINDER Vessel Configurator is the tool that gives you control over your requirements! “Configure it your way!” is more than just a motto; it is your ticket to the world of customized container solutions. Our user-friendly configurator allows you to perform precise volume calculations and design vessels according to your individual requirements. Whether you are preparing inquiries or optimizing your processes, with the BINDER Vessel Configurator, you have the tools to turn your visions into reality. The best part? The use is completely free of charge.